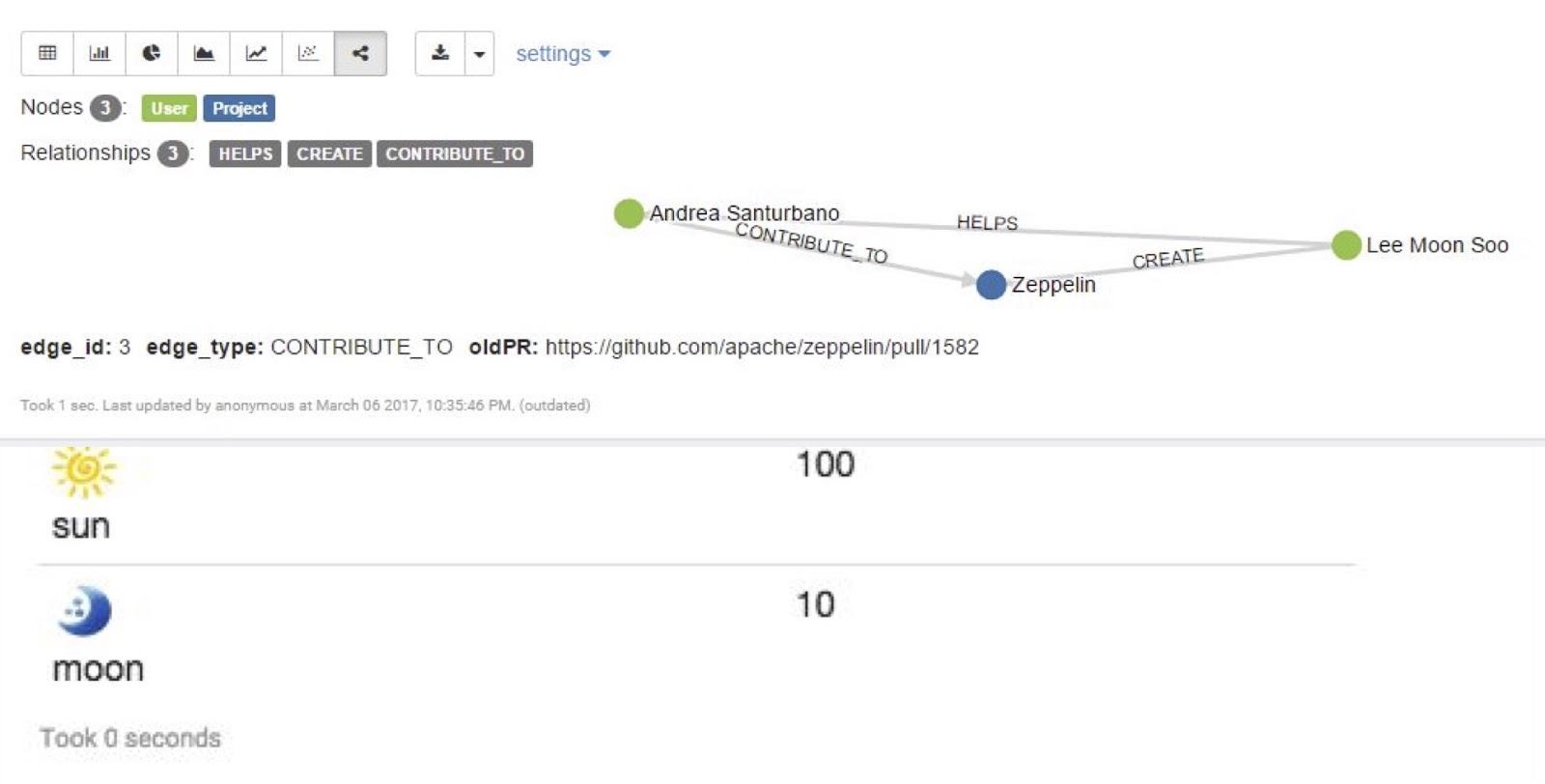

In a previous pictorial we showed you the great 'Trail Blazing No. 8' set from 1929, 'The Set that Builds the Zeppelin.' Well, here is the famous Zeppelin itself. This is surely the most dramatic and physically imposing of all the signature models from the Classic Period of Gilbert Erector. It is also remarkably realistic in appearance despite its relatively simple construction. This is due in no small part to the distinctive cloth cover emblazoned with the Erector logo that is laced over the girder framework. Fully assembled, the model measures nine inches in diameter and over four feet long from its bright red nose cap to its red and silver tail fins. The label from the inside of the No. 8 box lid is shown at right. It depicts an artist's rendering of the finished model docked to its mooring mast, along with a cutaway of the fuselage showing the girder framework under the outer cover.

The photo above shows the actual model, fully assembled and anchored to its mooring mast just as it appears in the box lid artwork. But, let's look at some details of its construction. The fuselage of the model is a simple open framework of 50 C 10' girders attached to five rings made from HK formed girders (see photos below).

Overview of the girder framework

Framework detail; each 'ring' is composed of five HK 5' formed girders

At the tail end of the fuselage the C girders are tied loosely together with string. Halfway between the tail end and the last ring of HK formed girders, the HP wire tail ring is tied to the C girders at four points to stabilize the rear end of the framework. At the front end of the fuselage the girders are pulled together and sandwiched between two HG nose caps (modified boiler tops). This construction is shown in the photo below. This can be a tricky thing to do, even with an extra set of hands to help you. But, here's a few tips that will make it fairly easy to do by yourself:

Front-end Angular API in Apache Zeppelin Basic Usage In addition to the back-end API to handle Angular objects binding, Apache Zeppelin also exposes a simple AngularJS z object on the front-end side to expose the same capabilities. In Pyrolyx’s lawsuit, filed in Vigo County Superior Court Division 1, the company claims Zeppelin Systems conducted front-end engineering and design for the company’s first plant in Terre.

- Form the nose before you tie the tail girders together so that you can stand the framework upright on them.

- Holding it horizontally, slip the HP wire tail ring down over the nose girders until it reaches the second screw hole. As you do this, the girders will be forced together. Push the ring down just below the hole on one side of the framework and slip a long screw through the hole; do the same on the opposite side of the frame (see photo below). The ring will hold the girder ends in nearly the exact position needed to fit on the nose caps.

- Bolt the two nose caps loosely together using 7/8' screws, leaving the caps separated about ½'. Slip the girder ends between the caps. When they are all in place, hold the upper cap with one hand and start tightening the screws with the other, alternating screws every few turns. Tension in the girders will force the two caps apart, keeping the nuts on the underside of the lower cap pressed against it as you tighten the screws: no wrench needed!

The nose caps in place

Use the tail ring to hold the nose girders together while installing the nose caps

With the fuselage complete, the next step is to slip on the cloth bag that forms the outer skin of the fuselage. The front foot or so of the bag is closed, except for a hole just large enough to slip tightly around the nose cap. The rest of the bag is open along the bottom; the seams sewn along the edges of the opening contain evenly spaced metal grommets. The bag slides onto the framework from the nose end, and is pulled down its length until it stops 3-4 inches from the tied ends of the C girders. A cloth cord supplied with the set is laced through the grommet (be careful here!). The ends of the cord are tied together to complete the installation of the bag. The photos below show the bag in place, and a detail of the lacing along its underside.

The girder framework fitted with the cloth bag and tail assembly

Detail of the lacing on the underside of the bag

The remainder of the model assembly involves building and installing the tail unit and the three gondolas. The tail unit consists of four rudders, or fins, screwed to the tail cap. The unit slips over the tied ends of the C girders, and one end of the tied lacing cord is slipped through the slot at the end of the tail cap and knotted to hold the cap in place. The gondolas consist of a propellor on a shaft that is screwed into a boss at the rear of each gondola car. Four hanging rods are attached to holes along the upper edge of each gondola car. Finally, the completed gondolas are suspended from CH angles that are screwed at intervals along the bottom of the framework. (If there is a shortcoming in the design of this model, it is here: 12 ½' slits must be cut in the cloth bag to accomodate the CH angles!). Detail photos of the tail and gondola assemblies are shown below.

Detail of the tail assembly

Detail of a gondola assembly

Zeppelin Front End

The next phase of this project, building the mooring mast, is optional. Some builders forego this, opting instead to display their completed Zeppelin models suspended from a ceiling. However, I wanted to build the entire design as depicted in the box art and in the instructions. The result is shown in the photos at right and below.

As designed by Gilbert, the mast is nothing more than a long, 'big channel' square girder with a simple platform at the top. If you look at the model instructions at the bottom of this page, you'll notice that the base of the mast is meant to be screwed to a board so that it will stand on its own. It will, but as designed it would never support the weight of the zeppelin when attached. So, I modified the base of the mast in an effort to overcome this problem. I opened up the bottom of the square girder by spreading the ends of the individual girders about 5 inches (see photos) to match the tower shown in the box art. Surprisingly, this simple change did the trick: when attached to a board, the mast is rock-solid, and even with over four feet of zeppelin sticking out horizontally from its top it remains almost perfectly vertical! This is a real testament to the structural strength of Gilbert's square girder concept.

I made one other modification to the original design by substituting S base plates for the shorter Q base plates in the upper platform. This makes for a much nicer look and a more functional structure (see photos below).

Finally, with the mast securely anchored to a board, the zeppelin can be attached. This is accomplished by means of the HQ zeppelin support rod. This rod is installed in the zeppelin framework prior to fitting the cloth bag. The long end of the HQ rod is slipped through the hole in the nose caps and then through a hole in a girder that is attached across the framework. A collar holds the rod in place. To mount the zeppelin on the mast, the short end of the rod that protrudes from the nose caps slides down through the two BAX bull wheel centers in the top of the tower. Notice in the photos that the HQ suport rod is not bent at a right angle, as you might expect. This is intentional: when the zeppelin is mounted on the mast, its weight flexes the rod downward so that it is suspended in a horizontal position.

Detail of the top of the mooring mast

The zeppelin framework mounted on the mast

Zeppelin Front End Video

Special Parts

The fifteen special parts used to build the Zeppelin model are shown in the photos below; all parts except the cloth bag are shown in relative scale. A detail of the gondola is also shown; this part is difficult to find in good condition today, because it was made from very thin, flexible metal that is easily deformed and is not much stronger than a soft drink can. The new parts are listed in the table below.

| Part No. | Part Name | Quantity |

|---|---|---|

| HD | gondola | 3 |

| HE | tail cone | 1 |

| HF | butt end plate | 2 |

| HG | nose cap | 2 |

| HI | gondola strut | 12 |

| HJ | propeller | 3 |

| HK | 5' girder, formed | 25 |

| HL | left rudder | 1 |

| HM | right rudder | 1 |

| HN | stabilizer | 2 |

| HO | cloth cover | 1 |

| HP | 6' ring | 2 |

| HQ | zepplin support rod | 1 |

| HS | propellor rod, 3' | 1 |

| BAX | bull wheel center, ¼' hub | 2 |

Special Zeppelin parts; the cloth bag is shown at a smaller scale than the other parts

Zeppelin Front End Cover

Detail of the gondola

Zeppelin Front End Crossword

Three pages in the No. 8 instruction manual were devoted to the new Zeppelin model. These pages are shown below.