A Forklift Fork is astructural component of the lift machine that are attachments, serving as the lifting surface. They are generally made of the highest grade of metal, although other durable materials with lesser weight are becoming viable alternatives today. These components are usually two pronged and are attached to a mast, which serves as the vertical stabilizer. This mast has rollers that hold the fork at the appropriate levels when loading and lifting pallets. To control them, a control module or positioner in the cab is used by the operator. This module energizes a hydraulic system that regulates the movement, vertical, horizontal and angular positioning of the fork.

Our used forklift inventory includes: used order pickers, used pneumatic forklifts, used cushion tire forklifts, used electric forklifts, used narrow aisle forklifts, used pallet jacks, used sit down rider forklifts, used rough terrain forklifts and used reach trucks. Thank you for letting Forklift Network™ help you with your next used. A forklift (also called lift truck, jitney, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, including Clark, which made transmissions, and Yale & Towne Manufacturing, which made hois.

- A Fork Clamp can operate both as a clamp and a fork positioner. Awkward loads, such as crates, bales & tires can be clamped between the forks. The ability to position the forks speeds pallet handling and reduces wear and tear on the pallets. Custom fork types and sizes are available.

- Clark Forklift Parts The company's North American Parts Distribution Center is located in Kentucky, USA, and comprises of more than 40,000 components with several product applications. All of Clark's products are designed, manufactured and delivered with a single motto “Built to last”, which aims at making customers' investment in its.

Forklift forks come in various sizes, which are categorized into classes. The most commonly used fork sizes are under class 2, 3, and 4. These sizes are measured at the carriage from the bottom of the upper hanger to the top of the lower hanger. Class 2 forks have 16 inches of distance between the top and bottom of carriage. Whereas, class 3 has 20inches and class 4 has 25 inches.

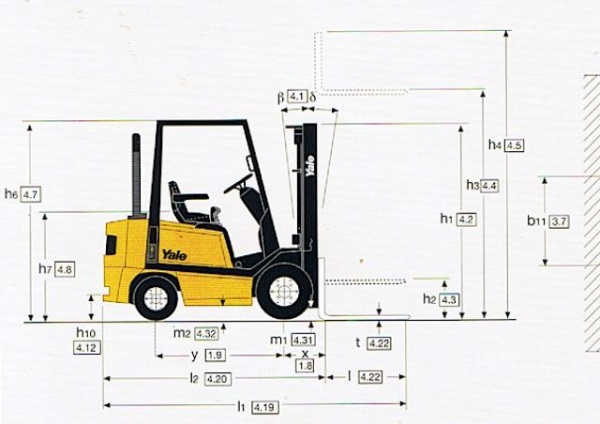

Other important information to keep in mind are the fork length, fork width and fork thickness. Fork length entails the distance from the end tip of the fork to the face of the vertical, carriage structure. Fork width refers to the measurement from side edge to the other side edge of a singular fork arm. The fork thickness means the measurement from the top to the bottom of the fork arm. Finally, the load capacity of the forklift is another important information. Found near the dashboard of the forklift, there is a data tag which includes the load capacity information.

Forklift forks are among the parts of a lift truck that is made to last long when used cautiously. But, due to its heavy use and perhaps its misuse, their service life takes a toll. Additionally, they wear over time as they get chipped or damaged. Some poor quality forks may fracture or break too depending on the load that is being moved.

Used Pallet Forks For Sale

Solid Lift Parts Inc. provides varieties of shapes and sizes of forklift forks. If your forklift is needing new forks, note all of the dimensions and load capacities, as described above, and contact your parts specialist right away. Here at Solid Lift Parts Inc., we aim to find you the correct part right away, at the most affordable prices, and ship them to you at your nearest available warehouse fast.

Used Forklift Forks On Ebay

Forklift Forks Photos